voestalpine Tubulars offers high quality tubes and components for construction machinery used in hydraulic cylinders, concrete pumps and construction solutions. Our products ensure maximum performance and reliability. voestalpine Tubulars’ products for construction machinery and related applications offer outstanding properties tailored to the needs of the industry.

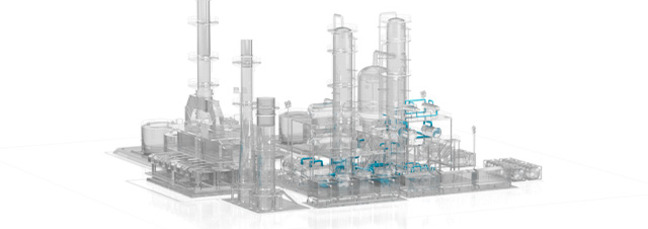

Our tubes and pipes for pressure applications ensure safety and efficiency in refineries, power plants and the chemical and petrochemical industries. They are ideal for heat exchangers, waste heat recovery and industrial high-pressure systems.

Areas of application:

Our pipes are characterised by their high resistance and first-class performance – even under extreme loads. Their robust design guarantees reliable functionality, even in the most demanding areas of application, such as

- Refineries / down stream – for hydrocarbon processing / media extraction

- Coal fired Power plants / Power Generation for heat transfer units

- chemical and petrochemical industry for waste heat recovery units

- Industrial high pressure plants/equipment

- Fittings and elbows

- Semi-finished products for hydraulic cylinders

- Accumulator shells and diving cylinders

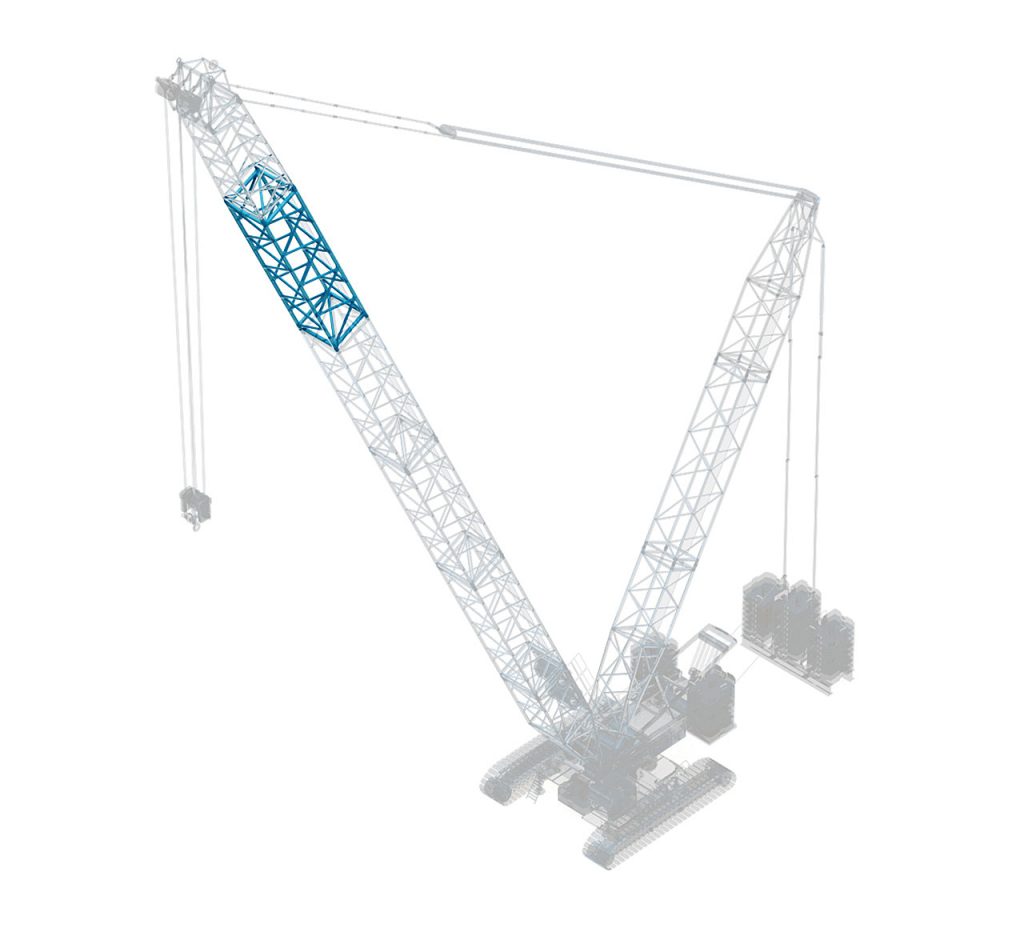

- Lattice boom sections for cranes

- Concrete pump pipes

- Oil and Gas (manifolds, perforation guns, stators for eccentric pumps)

- Roller coasters

- Agricultural equipment

Product characteristics and customer benefits:

- High pressure resistance and durability – Our tubes for hydraulic cylinders, accumulator shells and diving cylinders are characterised by high pressure resistance and durability, ensuring reliable performance in demanding environments.

- High strength and optimum stability – Tubes for lattice boom sections for cranes and concrete pumps are designed to withstand high loads while providing optimum stability.

- Increased efficiency and productivity – Our solutions for undercarriages and agricultural equipment contribute to efficiency and productivity, while products for the oil and gas industry, such as manifolds and stators for eccentric pumps, offer excellent corrosion and temperature resistance.

By combining these outstanding product features, our customers benefit from extended service life of their machines, reduced maintenance costs and an overall improvement in the efficiency of their applications. voestalpine Tubulars stands for reliability and quality that contribute to the success of your projects. For more information on our steel grades acc. to SEW 090-2 and EN 10210-3 visit our website or get in contact.

Customised product solutions

- Standardised or customised, the choice is yours – Find the optimum product solution with us!

Certified, safe and reliable

- Certifications in accordance with international standards guarantee the highest quality and conformity with environmental, safety, health and other important rules, regulations and values.

Tubes for pressure applications

- voestalpine Tubulars operates a quality management system that has undergone specific assessment for pressure equipment materials.

Standardised product solutions

- The main standards for our products for pressure applications are ASTM and EN.

Further benefits:

- Carbon steel and low alloy steel tubes are produced in dimensions from 26.70 to 200.00 mm (1.050 to 7 ⅞ inches), meeting both international standards and specific customer requirements. Testing with internationally recognised certificates can be carried out for custom solutions as the mechanical material testing facilities are accredited to ISO/IEC 17025:2017.

- Through annual customer satisfaction surveys and continuous development with our customers, we have established ourselves as a reliable partner for the entire process, from initial contact to after-sales service.

- Pressure Equipment Directive: Specific assessment of pressure equipment materials (PED 2014/68 / EU Annex I, Section 4.3) and certification by the competent body (TUEV SUED).

Pressure components: TÜV AD 2000 W0 / TRD 100 and AD 2000 W4